Our virus bank manufacturing track-record includes various families of viruses :

- Vaccinia

- Baculovirus

- Coxsackievirus

- Enterovirus

- Rubella

- Measles

- Dengue

- Adenovirus

- Influenza

- HIV1

- Rabies

- SARS-COV2

- …

Virus bank manufacturing is a crucial step in the production of biopharmaceuticals, such as vaccines and gene therapies.

Manufactured from characterized cell banks which serve as substrates, Master and Working Virus Seeds Stocks (MVSS, WVSS) contain virus stocks that are used as starting materials for the production of viral vectors or vaccine candidates (live attenuated virus or inactivated virus).

Virus bank production must ensure the quality, identity and stability of the virus banks, essential for the success of the downstream manufacturing process. Virus bank manufacturing must meet standards of the pharmaceutical industry. Hence, this key milestone requires strict adherence to guidelines and regulations issued by national or international authorities (EMA, FDA, ICH, etc.) to be compliant to cGMP expectations.

A CDMO licensed for GMP, Clean Cells provides virus bank production services for R&D and clinical applications. Naturally, to ensure a high quality of viral banks, Clean Cells offer services of cell bank manufacturing.

Virus banks manufactured inhouse benefit from an exclusive repertoire of assays for characterization following virus bank manufacturing and short or long-term storage services.

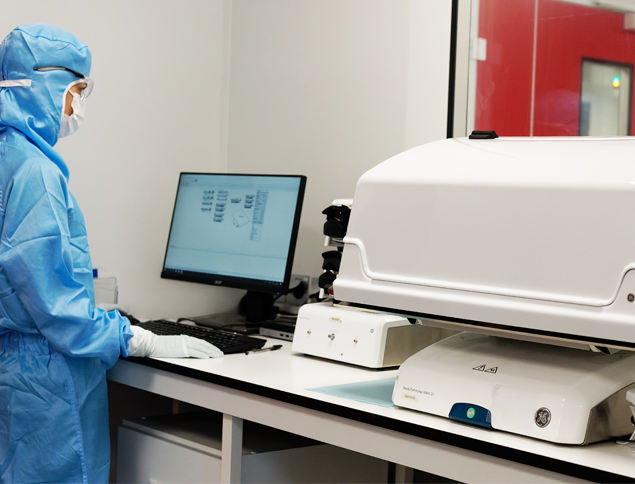

For many years, Clean Cells works with biosafety level 2 (BSL2) and 3 (BSL3) pathogens either for quality control or production of virus stocks. Our state-of-the-art manufacturing suites – BSL-2 and BSL-3 – with their negative pressure, their strict environmental control (Class C) and validated cleaning procedures allow the production of various wild or modified viral strains (DNA, RNA, enveloped or non-enveloped) for diverse applications (vaccines, oncolytic viruses, vectors).

Our strategy relies on an initial feasibility study to identify the best growth and technical parameters aligned with the sponsor’specifications, taking into account their data and expectations for environmental controls during virus bank manufacturing.

These parameters and controls are documented in Manufacturing Files according to cGMP guidelines and our GMP-audited QMS. Based on this study, a precise timeline is generated for virus bank manufacturing.

Our virus banks are grown from either adherent or suspension cell cultures, with the capacity to produce up to 500 vials per virus bank manufacturing campaigns.

Our virus bank manufacturing track-record includes various families of viruses :

To ensure the safety and reliability of virus banks for use in GMP processes, MVSS and WVSS must be characterized after virus bank manufacturing. Clean Cells is a biologics testing leader with over 200 assays for biosafety, potency, identity, and purity purposes.

Hence, Clean Cells is able to fully characterize the so-produced virus banks in cGMP conditions to ensure they can be used directly in GMP processes or safely stored as a one-stop-shop solution post virus bank manufacturing.

Our GMP testing labs and experts are supported by our audited quality system and work closely with virus bank manufacturing managers to ensure seamless projects and timelines, from initial feasibility study to final release.

Upon virus bank manufacturing and subsequent characterization, seed stocks may enter short or long-term storage. Clean Cells offers a panel of -80°C storage services in a qualified GMP environment to safely store virus banks prior to further usage in biomanufacturing.

Our sister company Naobios, which belongs to the Clean Biologics group, has the capability to produce biopharmaceutical substances used in clinical settings under cGMP conditions from these stocks. This allow for an integrated cGMP offer from R&D stocks to virus bank manufacturing to clinical production.

For more information, please do not hesitate to contact us.

"*" indicates required fields